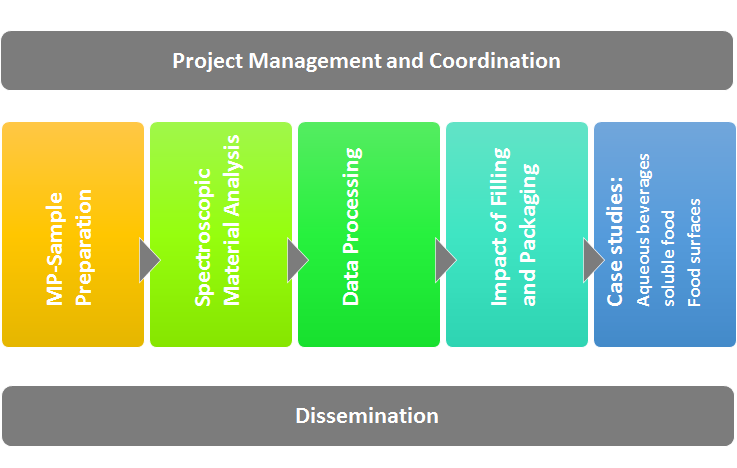

The project “microplastic@food” will be executed in five steps: in the first step (WP 2) the sample preparation and concentration will be optimized, and a MP-reference system will be generated. In the next step (WP 3) these MP-samples function as basis for the identification and quantification with FTIR- and Raman microscopy methods. All spectra collected from the MP reference samples undergo in WP 4 an automatic data processing step. Based on the validated method, in WP 5 samples from filling and packaging plants will be evaluated for MP (e.g. identification, quantification) followed by the analysis of food samples (WP 6) from beverages, soluble food and food surfaces. The work packages Project management (WP 1) and Dissemination (WP 7) accompanies the RTO work packages

WP1 - Project Management

In this work package, ecoplus, together with IVLV, takes over the project coordination from project planning, technical and financial management to reporting. At the beginning of the project, the consortium agreement is drawn up together with the research partners and the IP rules are negotiated. During the project, meetings of the steering committee are organised, and the progress of the project is communicated to the participating company partners and interim results are discussed. In the area of project controlling, attention is paid to the timely achievement of the milestones and - if necessary - corrective measures are defined in the work plan.

WP2 - Preparation Microplastic Reference Material

In the first step, MP reference samples (composition known i.e. the most important packaging plastics including PP, PE, PVC, PU, PET, PS, ABS, PA, PC, PMMA, PAN, PLA, PMDS, PVPP as well as plastic fibres such as PET, PAN) will be produced in three size classes - 1000-50 µm, 50-10 µm, 10-1 µm for the development and calibration of spectroscopic methods, for laboratory comparisons and the development of automated data analysis tools (-> WP 3 and WP 4). Furthermore, a general sampling protocol (SOP) will be developed for sampling in filling and packaging plants as well as at the production line and in ambient air (-> WP 5). In a further preparatory step, an SOP is drawn up for sample preparation, cleaning and concentration procedures for the product groups: Water and filtered beverages, milk and liquid dairy products, soluble foods (e.g. salt, sugar) and surfaces of packaged foods (rinsing liquid) for spectroscopic analysis (Raman & FTIR) (-> WP 6).

WP3 - Spectroscopic Material Analysis

In the first step, analytical methods based on vibrational spectroscopy (IR and Raman microscopy) will be established for the detection and identification of MP (enriched on special filters (-> WP 2). For this purpose (a) SOPs for imaging, identification and quantification of MP have to be implemented and validated and (b) existing spectral databases for samples within this project have to be established and completed and (c) a practical detection limit for the determination of MP particles for high throughput analysis and for the different sample types within this project have to be defined (guidelines). Furthermore, qualitative and quantitative determination of MP particles will be performed on reference samples and comparison of the different analytical approaches will be made. Decide (i) which analytical approach is best suited for which sample type (water, beverages, food,...) and (ii) which approach is simpler, more reliable and above all faster for specific requirements.

WP4 - Computer-aided Identification of Microplastics (Automation)

The collected FTIR and Raman spectra of the reference samples - of the most important polymers, as prepared in WP 2 and measured in WP 3, will be processed with automatic data processing algorithms of the Purency software. After an initial calibration and test phase, the spectral data of the reference samples including Establishment of a validated approach for computer-aided visualisation (size, shape), counting and identification (data processing) of MP particles for individual polymer types (all analytical methods) will be prepared. The results of the AI will be verified by visual checks and both the identification and quantification of the polymers will be continuously improved in revision cycles.

WP5 – Evaluation of the Packaging and Filling Systems

Samples are taken from various filling and packaging lines directly on the production lines and in ambient air according to the general sampling protocol developed in WP 2. The samples will be analysed for MP contamination that could be introduced at different stages in the packaging and filling lines (e.g. before and after filling, at intermediate stages of the production line). Thus, potential sources of MP input and/or generation along packaging and filling processes (ambient air, production equipment, abrasion in production lines) can be investigated and measures to avoid MP in food, beverages and packaging can be derived.

WP6 - Application in Case studies (I) Beverages, (II) Soluble Foods (Salt, Sugar), (III) Complex Packaged Foods that are rinsed off

Sampling and analysis of potential MP contamination of 3 product categories: Beverages, soluble foods and food surfaces. The step-by-step SOP description of the sample preparation procedure for aqueous samples (mineral water, rinsing solutions, dissolved powder solutions) developed in WP 2 is applied.

Case study I Water, beer, milk and filtered beverages:

In this task, samples of mineral and spring water, milk and filtered beverages such as juices are analysed for MP contamination. Samples of the participating project partners (anonymised) are analysed, and the effect of the different interfering beverage matrices are removed, as milk fat or sugar contaminations have a negative effect on the measurability MP and complicate the spectroscopic sample identification. The results of the qualitative and quantitative analysis as well as possible avoidance measures to reduce potential MP contamination are discussed with the respective customer.

Case study II soluble foods:

Different types of water-soluble foods (salt, sugar, ...) are the target of the second case study. Solutions of the participating partners' products are sampled and analysed for potential MP contamination. The step-by-step SOP description of the sample preparation procedure for aqueous samples (mineral water, rinsing solutions, dissolved powder solutions) developed in WP 2 will be applied.

Case study III Food surfaces:

MP can also be found on different types of packaged food (e.g. cheese blocks or sausage) caused by MP contamination in the packaging line. Therefore, the food surfaces are the target areas to be rinsed and the eluate analysed. The products of the participating project partners are rinsed after unpacking, filtered and analysed for possible MP contamination.

In order to draw conclusions about the potential sources of MP contamination and to find possible solutions to reduce MP contamination, individual discussions are held with the respective customers.

WP7 – Dissemination

In work package 7, the results of the project will be made accessible to the interested public, on the one hand via the website, but also via scientific lectures („Österr. Verpackungstag") and publications (e.g. „Environmental Science & Technology", „Analytical Method", „Applied Spectroscopy"). Another goal is to compile and publish a catalogue of countermeasures to reduce MP in food and food packaging and filling equipment. Continuous participation in standardisation bodies such as Austrian Standards International (ASI), Committee ON-AG 074 09 and the International Organisation for Standardisation (ISO), Committee ISO/TC 61/SC 14/WG 4, is essential to enable a bidirectional transfer of knowledge and to contribute to the harmonisation process of MP measurement approaches.